Iveco Astra HD9

(Quarry, Mine and Construction Vehicle Category)

About The Model:

The new generation of cars Astra HD9 combines 60 years of experience in the highly specialised field of production of heavy trucks and the latest technology, which can be seen on the new cab and bright design, as well as a significant increase in comfort for the driver. Increased comfort, improved visibility thanks to large windows and a new rear-view mirrors, original and cutting-edge design - these are the innovations, which in combination with the recognised reliability of the chassis and drive system make the new Astra model HD9 ideal choice for those who require maximum performance in any conditions.

ASTRA HD 9 vehicles have been synonymous of efficiency, reliability, performance on construction sites, quarries and mines all over the world. In the most extreme climatic conditions, from the heat of African deserts to the intense cold of Arctic regions.

The NEW HD9 SERIES.

Powerful, feature-rich and versatile:

- 11 configurations, 2, 3 and bridge 4 and complete wheel drive, in an embodiment of a truck or tractor.

- 8 engines with different cylinder capacity: 380HP to 560HP in versions Euro 5 or Euro-3, depending on the market

- More than 100 base models, each of which has a different length and are available in different embodiments, including a model configuration HHD truck or tractor to perform very complex tasks.

Increased business productivity and higher safety and comfort for drivers.

The utmost specialisation in building site, special purposes and heavy duty haulage vehicles.

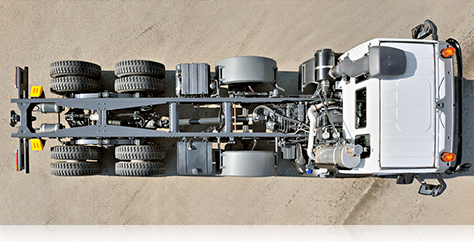

With the introduction of the new steel cab, installed on the well-known Astra frame made of two parallel side members, the HD9 range reinforces its leadership among highly specialised off-road vehicles, by achieving a perfect balance between comfort and extreme performance.

The features of these vehicles - versatile yet tough at the same time - and the nearly unlimited customisation options mean that you can configure your Astra whatever your transport and construction site needs and wherever you are worldwide, from quarries and construction sites, to oversized loads and specialist oil & gas sector applications.

Different Models include: HD9 Euro 3 and HD9 Euro 5; HD8 Euro 3 and HD8 Euro 5

Technical characteristics:

Cursor Engines

Cursor engines with a displacement of 13 liters, electronically controlled pump-injector and camshafts provide excellent elasticity and great stopping power, which is very important for the operation of the vehicle on the construction site due to the excellent performance of torque throughout the rev range of the engine and a new exhaust brake in the exhaust system motor.

Transmission

The whole range of transmissions HD9 new model has been developed to perform the most complex and demanding. To ensure flexibility and versatility of its vehicles, the company offers a wide range of Astra transmissions, satisfying all requirements.

Manual

Adapted manual gearbox ZF technology Ecosplit 4, with 16 gears to move forward and 2 gears to reverse, as well as improved and upgraded servo synchromesh clutch, providing the driver a great help especially when driving with a load.

Robotic box

Astronic ZF with 16 gears and drive clutch and gearshift.

This transmission allows the driver to intervene at any point in its work,

moving from automatic to manual mode switching.

Automatic

Allison 4700 with 7 gears to move forward and 1 gear to reverse.

Main gear

Astra Company offers bridges axles maximum load of 8 to 9 tons for vehicles in any configuration with incomplete or complete drive (with the appropriate tires and suspension). In addition, depending on the type of operation the customer can choose the most suitable for his final drive ratio in the range of 3.793 to 6.588.

For some models (6x6 and 8x6) and for extremely heavy-duty can be ordered reinforced axle Kessler with a maximum load of 8 m (maximum speed of 90 km / h) to 10 m (maximum speed of 70 km / h) with special axle ratio.

Suspension

Cars model line HD9 equipped with parabolic leaf springs on the front and rear axles for enhanced comfort and noise reduction. As laboratory and practical tests confirmed that during normal operation of the vehicle the average life of the parabolic springs is two times higher than the previous design.

For installation with a high center of gravity and heavy-duty vehicle on request can also be equipped with a semi springs.

semi-elliptic leaf springs and pressure molded earrings, designed with the high degree of security, can achieve the highest level of quality in this segment.

rakes

On models HD9 used drum brakes with two Lug devices (Duo Duplex) at each wheel for a more balanced braking and more even wear mechanisms, thereby increasing their lifespan.The brake system is kept clean through the air treatment unit APU, which includes several valves.

deceleration control system implemented EBL (electronic braking force limiting system) system and ABS, which provide a braking force to each wheel without the risk of being locked regardless of the load vehicle.